HEAT PUMP

Heat pumps work by transferring heat from warmer areas to cooler areas. This represents huge energy savings compared to heating cool air.

Heat pumps are a proven and reliable technology in Canada, capable of providing year-round comfort control for your home by supplying heat in the winter, cooling in the summer. They work by extracting heat from a low-temperature place and delivering it to a high-temperature place.

In the summer, this means taking heat from your home and depositing it outdoors. In the cooler months, they take heat from the outdoors and deliver it indoors.

You may not think that this is possible however, heat is all relative. Heat naturally flows from places with higher temperatures to locations with lower temperatures. The heat pump extracts the energy from the higher temperature area and delivers it to the lower temperature area.

Heat pumps are fully reversible meaning they work in both directions – either bringing warm air into the home or bringing warm air out of the home. Once the heat is extracted it is delivered to the rest of the home through the duct system.

Since the electricity is used to transfer heat rather than create it heat pumps can be more than 100% efficient. That means more thermal energy is produced than the amount of electric energy used to pump it. This will depend greatly on the overall temperature difference. If you think of riding a bike up a hill there is a lot of energy required to go up a steep hill compared to a shallow one. In the same way, if the temperature difference is “steep” it will require more energy.

This video explains how the heat is transferred through the system.

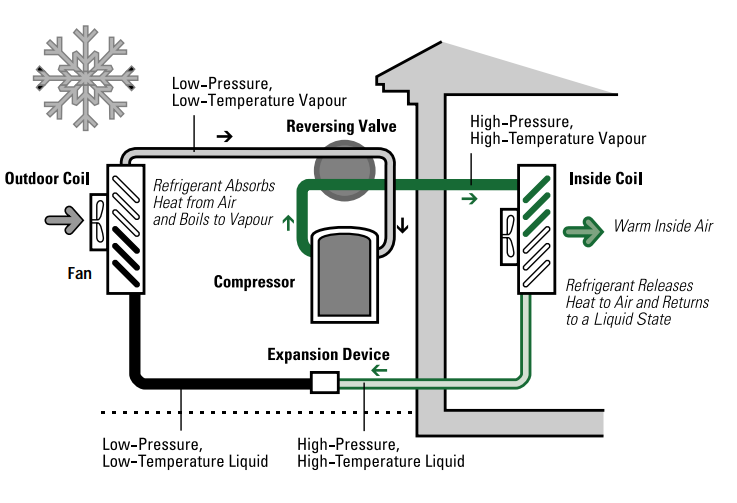

The Heating Cycle

During the heating cycle, heat is taken from outdoor air and “pumped” indoors.

- First, the liquid refrigerant passes through the expansion device, changing to a low-pressure liquid/vapour mixture. It then goes to the outdoor coil, which acts as the evaporator coil. The liquid refrigerant absorbs heat from the outdoor air and boils, becoming a low-temperature vapour.

- This vapour passes through the reversing valve to the accumulator, which collects any remaining liquid before the vapour enters the compressor. The vapour is then compressed, reducing its volume and causing it to heat up.

- Finally, the reversing valve sends the gas, which is now hot, to the indoor coil, which is the condenser. The heat from the hot gas is transferred to the indoor air, causing the refrigerant to condense into a liquid. This liquid returns to the expansion device and the cycle is repeated. The indoor coil is located in the ductwork, close to the furnace.

The ability of the heat pump to transfer heat from the outside air to the house depends on the outdoor temperature. As this temperature drops, the ability of the heat pump to absorb heat also drops. For many air-source heat pump installations, this means that there is a temperature (called the thermal balance point) when the heat pump’s heating capacity is equal to the heat loss of the house. Below this outdoor ambient temperature, the heat pump can supply only part of the heat required to keep the living space comfortable, and supplementary heat is required.

It is important to note that the vast majority of air-source heat pumps have a minimum operating temperature, below which they are unable to operate. For newer models, this can range from between -15°C to -25°C. Below this temperature, a supplemental system must be used to provide heating to the building.

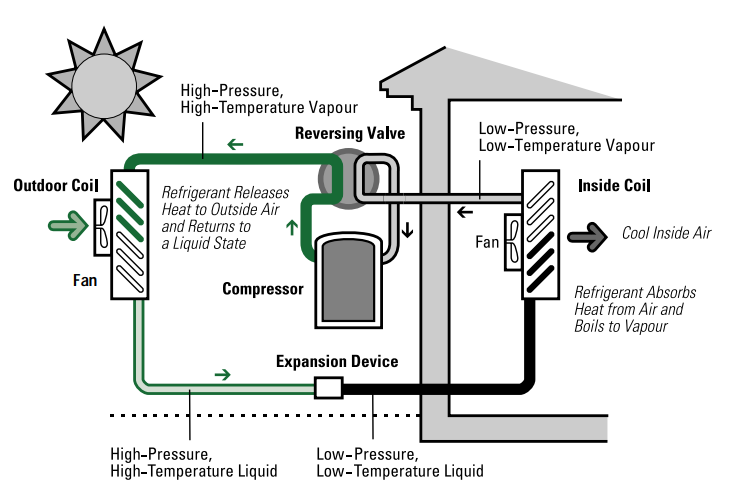

The Cooling Cycle

The cycle described above is reversed to cool the house during the summer. The unit takes heat out of the indoor air and rejects it outside.

- As in the heating cycle, the liquid refrigerant passes through the expansion device, changing to a low-pressure liquid/vapour mixture. It then goes to the indoor coil, which acts as the evaporator. The liquid refrigerant absorbs heat from the indoor air and boils, becoming a low-temperature vapour.

- This vapour passes through the reversing valve to the accumulator, which collects any remaining liquid, and then to the compressor. The vapour is then compressed, reducing its volume and causing it to heat up.

- Finally, the gas, which is now hot, passes through the reversing valve to the outdoor coil, which acts as the condenser. The heat from the hot gas is transferred to the outdoor air, causing the refrigerant to condense into a liquid. This liquid returns to the expansion device, and the cycle is repeated.

During the cooling cycle, the heat pump also dehumidifies the indoor air. Moisture in the air passing over the indoor coil condenses on the coil’s surface and is collected in a pan at the bottom of the coil. A condensate drain connects this pan to the house drain.

The Defrost Cycle

If the outdoor temperature falls to near or below freezing when the heat pump is operating in the heating mode, moisture in the air passing over the outside coil will condense and freeze on it. The amount of frost buildup depends on the outdoor temperature and the amount of moisture in the air.

This frost buildup decreases the efficiency of the coil by reducing its ability to transfer heat to the refrigerant. At some point, the frost must be removed. To do this, the heat pump switches into defrost mode. The most common approach is:

- First, the reversing valve switches the device to the cooling mode. This sends hot gas to the outdoor coil to melt the frost. At the same time the outdoor fan, which normally blows cold air over the coil, is shut off in order to reduce the amount of heat needed to melt the frost.

- While this is happening, the heat pump is cooling the air in the ductwork. The heating system would normally warm this air as it is distributed throughout the house.

One of two methods is used to determine when the unit goes into defrost mode:

- Demand-frost controls monitor airflow, refrigerant pressure, air or coil temperature and pressure differential across the outdoor coil to detect frost accumulation.

- Time-temperature defrost is started and ended by a pre-set interval timer or a temperature sensor located on the outside coil. The cycle can be initiated every 30, 60 or 90 minutes, depending on the climate and the design of the system.

Unnecessary defrost cycles reduce the seasonal performance of the heat pump. As a result, the demand-frost method is generally more efficient since it starts the defrost cycle only when it is required.

This description and diagrams of how a heat pump works is taken from nrcan.gc.ca. For more information visit their website here.